How Precision Engineering Transforms SM PCB Boards into Tech Marvels?

Wiki Article

The computerized transformation has moved the advancement of electronic gadgets, making them littler, more effective, and proficient. At the heart of these cutting-edge gadgets lie SMT PCB boards (Surface Mount Technology Printed Circuit Boards), where designing accuracy plays a significant part in changing them into mechanical wonders. This Substance digs into the ways accuracy designing hoists SMT circuit boards to unparalleled levels, giving understanding into their advancement, applications, and future potential.

The Essentials of SMT Circuit Boards

To appreciate the transformative control of accuracy designing, one must to begin with get it what SMT circuit boards are. Not at all like conventional through-hole PCBs, surface mount PCBs utilize a Technology where electronic components are straightforwardly mounted onto the surface of the board. This plan improves compactness, proficiency, and versatility, making SMT PCB boards the go-to arrangement for cutting edge electronics.

Understanding SMT PCB Boards: A Foundation of Cutting edge Electronics

A Surface Mount PCB (Printed Circuit Board) is a modern stage that gives electrical associations and mechanical bolster to components in electronic gadgets. Not at all like conventional through-hole Technology, SMT (Surface Mount Technology) eliminates the need for drilled holes,, permitting components to be mounted specifically onto the PCB's surface. This not as it were spares space but too improves the execution and unwavering quality of electronic systems.

Key characteristics of SMT circuit boards include:

· Miniaturization: Components utilized in SMT are much littler than those in through-hole designs.

· Efficiency: Upgraded electrical execution and diminished flag commotion due to shorter association paths.

· Cost-effectiveness: Optimized fabricating forms altogether lower generation costs.

· Versatility: Utilized in a run of businesses counting broadcast communications, car, healthcare, and customer electronics.

Advantages of Surface Mount PCB Technology

1. Compact Arrange and Space Efficiency

The SMT PCB Board is celebrated for its capacity to reinforce high-density circuitry. By apportioning with the require for through-hole affiliations, makers can fit more components into more diminutive spaces. This compactness is urgent for contraptions such as sharp phones, wearable, and IoT gadgets.

2. Moved forward Execution and Reliability

Surface Mount PCBs donate shorter electrical ways, reducing hail hindrances and advancing in common execution. The arrange securing of components progresses mechanical soundness, making contraptions more strong underneath thrust and vibration.

3. Cost-Effective Manufacturing

The automation-friendly nature of SMT era reduces work costs and increases efficiency. Robotized pick-and-place machines can handle gigantic volumes of SMT Circuit Boards with exactness, ensuring unfaltering quality.

The Role of Precision Engineering in SMT PCB Board Production

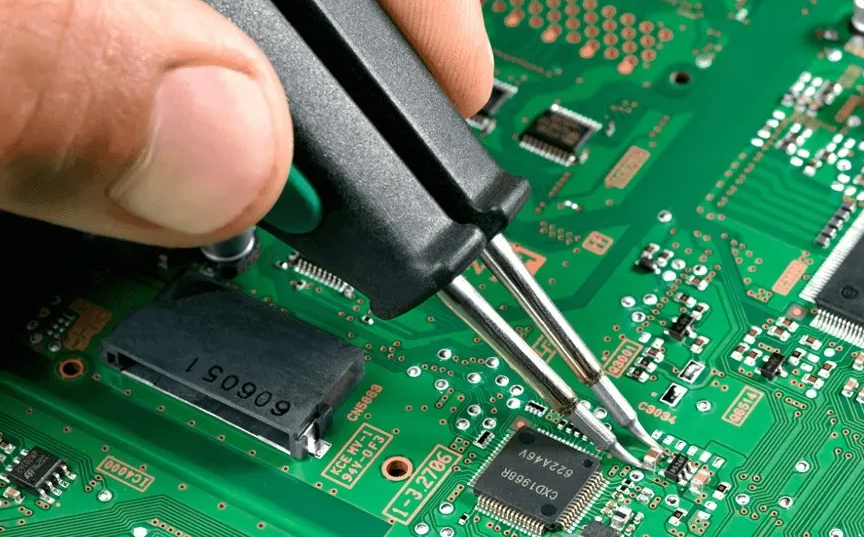

Precision building includes planning and creating parts with fastidious consideration to exactness and detail. For SMT circuit boards, it impacts each organize of the fabricating handle, from component arrangement to quality testing. Here’s how exactness building contributes to their transformation:

1. Progressed Plan and Prototyping

Before a surface mount PCB comes to generation, it experiences thorough plan and prototyping. Exactness building instruments like Computer-Aided Plan (CAD) computer program permit engineers to make nitty gritty schematics that foresee component execution beneath different conditions. This arrange involves:

· Simulation: Testing electrical behavior, warm resistance, and mechanical stresses virtually.

· Layering Accuracy: Multi-layered SMT PCB boards are planned with minuscule precision, guaranteeing flag integrity.

· Prototyping with Added substance Methods: Fast prototyping advances empower fast emphasess of SMT circuit boards, minimizing mistakes some time recently mass production.

2. Component Choice and Placement

One of the most basic angles of SMT PCB board generation is component arrangement. Given the decreased estimate of components, accuracy designing is fundamental to guarantee correct arrangement and arrangement. Robotized pick-and-place machines utilize high-resolution cameras and exactness spouts to put components with micrometer-level precision, optimizing:

· Density: Maximizing the number of components on the board without compromising functionality.

· Connectivity: Guaranteeing ideal patch joints for consistent electrical conductivity.

3. Soldering and Assembly

The soldering prepare for surface mount PCBs is where components are reinforced to the board. This requests uncommon accuracy to dodge abandons like cold patch joints or bridging. Procedures impacted by accuracy building include:

· Reflow Soldering: Guaranteeing uniform warm dissemination for reliable soldering quality.

· Solder Glue Application: Exact stencil plans guarantee the adjust sum of glue is connected to each pad.

· SMT PCB board Automated Optical Review (AOI): Utilizing machine vision to identify blemishes in soldering and assembly.

4. Quality Confirmation and Testing

Every SMT circuit board experiences rigid testing to approve its usefulness and solidness. Accuracy designing drives these testing strategies, which include:

· X-ray Review: Non-destructive testing to look at covered up patch joints and inner connections.

· Functional Testing: Guaranteeing the PCB performs its expecting assignments beneath recreated real-world conditions.

· Environmental Push Testing: Checking flexibility against temperature changes, stickiness, and vibrations.

Applications of Precision-Engineered SMT PCB Boards

The flexibility of surface mount PCB boards is apparent in their applications over assorted businesses. Let’s investigate how precision-engineered SMT PCB boards have ended up crucial in different sectors:

1. Consumer Electronics

From smart phones and tablets to wearable gadgets, SMT PCB boards are the spine of shopper hardware. Their compact estimate and vitality effectiveness enable:

· Miniaturization of Contraptions: Slimmer gadgets with more prominent functionality.

· Enhanced Solidness: Precision-engineered associations that withstand visit use.

· Better Flag Preparing: Made strides execution for high-frequency circuits in savvy devices.

2. Automotive Industry

Modern vehicles depend on a organize of SMT PCB boards for basic frameworks such as route, infotainment, and Advanced Driver Assistance Systems (ADAS). Exactness building ensures:

· High Unwavering quality: Components persevere unforgiving working conditions like extraordinary temperatures and vibrations.

· Seamless Communication: Exact information transmission over vehicle systems.

· Electrification: Empowering proficient control administration SMT circuit boards in electric vehicles (EVs).

3. Healthcare Technology

Medical gadgets request remarkable exactness and unwavering quality. SMT circuit boards are necessarily to gear like pacemakers, symptomatic imaging frameworks, and convenient screens. Key benefits include:

· Miniaturized Plans: Compact therapeutic gadgets for non-invasive diagnostics.

· Zero Resilience for Blunders: Accuracy designing minimizes the chance of malfunction.

· Customizability: Versatile plans custom-made to particular restorative requirements.

4. Telecommunications

The development of 5G and IoT (Internet of Things) has increased the request for strong SMT PCB boards. Accuracy designing enables:

· High-Speed Network: Taking care of expanded information exchange rates efficiently.

· Reduced Flag Misfortune: Upgraded execution for remote networks.

· Compact Framework: Littler, more proficient circuit boards for communication towers and devices.

5. Mechanical Automation

In industrial facilities and mechanical settings, SMT circuit boards control mechanical technology, sensors, and control frameworks. They offer:

· Durability: Resistance to wear and tear in rough environments.

· Precision Control: Precise estimations and mechanized responses.

· Energy Productivity: Lower control utilization for maintainable operations.

Advancements in Exactness Designing for Surface Mount PCBs

The continuous advancement of SMT PCB boards is to a great extent driven by developments in exactness building. These headways include:

1. Nanotechnology

Integrating nanotechnology with accuracy designing has revolutionized the manufacture of SMT circuit boards. Nano-coatings and nano-sensors make strides board strength and execution at an nuclear level.

2. AI and Machine Learning

Artificial Insights (AI) plays a imperative part in improving accuracy amid plan, fabricating, and testing. Machine learning calculations optimize pick-and-place precision, distinguish blemishes amid assessment, and foresee potential failures.

3. 3D Printing

Additive fabricating strategies permit for quick prototyping and generation of complex plans for SMT PCB boards. 3D printing ensures:

· Flexibility in Plan: Making unusual geometries.

· Reduced Squander: Exact fabric utilization amid production.

4. Laser Technology

Precision laser machining encourages precise cutting, boring, and stamping of PCB substrates. It enables:

· Enhanced Determination: Fine detail work for micro-sized components.

· Clean Forms: Negligible warm affect on delicate materials.

5. Computerization and Robotics

Automation fueled by mechanical technology guarantees unparalleled consistency and speed amid fabricating. Collaborative robots handle sensitive operations with human-like smoothness but more prominent accuracy.

Challenges in Exactness Building of SMT PCB Boards

While the benefits are colossal, exactness building in SMT circuit board generation faces a few challenges:

· Miniaturization Restrictions: Contracting components assist whereas keeping up execution and durability.

· Thermal Administration: Guaranteeing compelling dissemination of warm from thickly stuffed components.

· Material Restrictions: Creating modern substrates with way better electrical and warm properties.

· Cost Suggestions: Adjusting tall accuracy prerequisites with affordability.

The Future of SMT PCB Boards

As Technology propels, the part of exactness building in SMT circuit boards will as it were develop. Future advancements are likely to include:

· Flexible and Wearable Hardware: SMT PCB boards will bolster gadgets with versatile plans for clothing and accessories.

· Green Manufacturing: Precision-engineered PCBs optimized for quantum devices.

· Green Manufacturing: Feasible generation strategies diminishing electronic squander and asset consumption.

· Increased Automation: More noteworthy dependence on AI and mechanical technology for proficiency and precision.

Conclusion

The change of SMT PCB Boards into mechanical wonders is a confirmation to the control of exactness building. By guaranteeing fastidious plan, fabricating, and testing forms, engineers can make Surface Mount PCBs that are littler, quicker, and more solid than ever some time recently. These advancements have not as it were revolutionized businesses but too cleared the way for groundbreaking headways in technology.

From consumer electronics to aviation frameworks, SMT Circuit Boards proceed to thrust the boundaries of what’s conceivable. As exactness building advances, we can anticipate these boards to ended up indeed more fundamentally to the gadgets and frameworks that shape our future. Whether it’s the improvement of more brilliant contraptions, independent vehicles, or progressed therapeutic gadgets, the part of precision-engineered SMT PCB Boards is evident, cementing their status as the spine of advanced Technology.